When affixing the CE Mark and placing a product on the market you will want peace of mind that it is not going be responsible for any injury and/or subsequent law suits. This is where a risk assessment can be beneficial by identifying potential hazards associated with the use of the product. With products falling under some Directives, such as the Machinery Directive, it is a mandatory part of the CE marking process. However with other Directives such as the Low Voltage (LV) Directive for electrical products it is not a mandatory requirement.

When affixing the CE Mark and placing a product on the market you will want peace of mind that it is not going be responsible for any injury and/or subsequent law suits. This is where a risk assessment can be beneficial by identifying potential hazards associated with the use of the product. With products falling under some Directives, such as the Machinery Directive, it is a mandatory part of the CE marking process. However with other Directives such as the Low Voltage (LV) Directive for electrical products it is not a mandatory requirement.

Most people have heard of the urban legend concerning the old lady microwaving her dog in an attempt to dry it. Whilst the legitimacy of this tale may be questionable, it is a good example of how a risk assessment could be used to demonstrate that all types of potential hazards have been considered and mitigated (even the ones that are extreme cases of misuse!). The common approach for CE Marking electrical equipment is to apply a standard that will identify the more generic and obvious hazards associated with a product, but a risk assessment should help to identify the less obvious ones (that may not be within the product standard).

Whilst the Low Voltage Directive does not legally require a risk assessment to be undertaken, there seems to be an emerging trends of the suggestion to use a risk assessment in some of the more recently updated commonly applied harmonised electrical safety standards. Lets not forget that standards are voluntary, but offer an effective way to prove compliance to Directives. The utilisation of a risk assessment helps to mitigate any residual risks that may not be covered even by using a harmonised standard, ensuring that products are even safer. Some examples of harmonised electrical standards incorporating a risk assessment follow:

– EN 60204-1 for the safety of electrical machinery

– EN 61010-1 for the safety requirements for electrical equipment for measurement, control and laboratory use

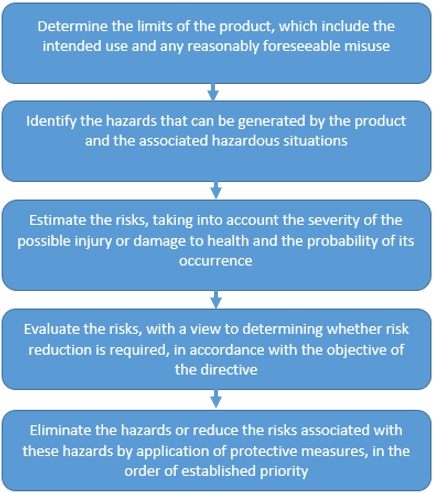

There isn’t a defined process to follow for undertaking a risk assessment on electrical equipment however there are a number of methods that could be used; such as the HSE ‘5 steps’ and the preliminary hazard analysis method. The risk assessment process within the Machinery Directive is a good example of a process that can be followed and is illustrated below:

By using a risk assessment method, potential hazards can be easily identified and mitigated to limit hazardous occurrences and keep users safe during the expected usage and lifespan of the product. And if you were wondering about microwave ovens, if you read the instructions I am sure that you will find a statement along the lines of ‘Only heat food products’ in there somewhere.

If you need further help with undertaking a CE Marking Risk Assessment for your electrical product or machine, then please call the technical team on 01527 595066.

As you may well know, the CE Marking Association moved offices in 2013 to Wootton Park, and one of the great benefits of moving was to feature a larger electrical test lab. To celebrate the launch of our new lab, we are running a very special offer to the first 20 customers.

As you may well know, the CE Marking Association moved offices in 2013 to Wootton Park, and one of the great benefits of moving was to feature a larger electrical test lab. To celebrate the launch of our new lab, we are running a very special offer to the first 20 customers. We would like to wish everyone a very Merry Christmas and a happy new year. This year has been extremely important for the CE Marking Association, as we celebrated 20 years of supporting UK manufacturers with their CE Marking and other product conformity requirements. Also as part of our efforts to continuously improve and expand our services, we moved offices in September to our new facilities at Wootton Park, which provided us with the opportunity to open our new larger electrical test lab and to provide better training facilities.

We would like to wish everyone a very Merry Christmas and a happy new year. This year has been extremely important for the CE Marking Association, as we celebrated 20 years of supporting UK manufacturers with their CE Marking and other product conformity requirements. Also as part of our efforts to continuously improve and expand our services, we moved offices in September to our new facilities at Wootton Park, which provided us with the opportunity to open our new larger electrical test lab and to provide better training facilities.