Equipment intended to be used in potentially explosive atmospheres that is being sold in Europe is required to be CE Marked under the ATEX Directive. The Equivalent UK legislation is the ATEX Regulations 2016

Where there is a mixture of air and a flammable substance (such as a gas, vapour, mist or dust), then there is the potential for an explosion to occur. All the mixture requires is a source of ignition. Where equipment has to operate in such atmospheres, then clearly it is crucial to ensure that the equipment does not provide the source of ignition. For equipment being placed on the UK and European market, this will come under the European Directive for ‘Equipment and Protective Systems Intended to be used in Potentially Explosive Atmospheres’ (or more commonly known as the ATEX Directive).

A unique aspect of the ATEX Directive is the ties it has with the user legislation. The Directive requires the manufacturer to design their equipment to be suitable for use within their customer’s explosive atmosphere. Therefore they need to rely upon their customer to give them information about the classification of the zone and the flammable substance(s) within that zone. This is where the user legislation comes in handy, as it will put the responsibility upon the end user to only source and use appropriate equipment within their potentially explosive zones. In the UK this user legislation is called DSEAR. The only responsibility the manufacturer has is to ensure that the equipment complies with the product legislation, this being the ATEX Directive (and any others that may also apply).

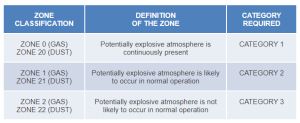

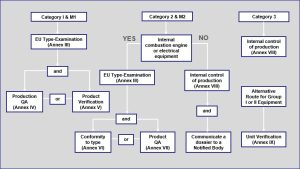

The route to conformity is based upon the category of the equipment and also whether it is mechanical and/or electrical. The first stage is to understand whether the equipment is intended to be used underground in a mine or whether it is above ground. For mines there are two categories M1 and M2, and for above ground there are three categories (1, 2 & 3) depending upon the zone.

Using this information manufacturers can then establish the appropriate route to conformity. The routes are summarised below:

The ‘Internal Control of Production’ procedure is a self-declaration route that does not require the involvement of a third party or a Notified Body for CE Marking. All of the other conformity procedures require the manufacturer to appoint a Notified Body. The full requirements of the conformity procedures are explained within the Annexes of the Directive.

The CE Marking Association can assist manufacturers of machines and products that need to comply with the requirements of the ATEX Directive. Some of the services on offer include:

For more support on CE Marking under the ATEX Directive, or to find out how we can help you, please contact us as below: